There are 3 sub-categories in this category

Sub-Categories

-

Types of Drip Edge

Types of Drip Edge

- (3 images)

- Hits: 100,727

-

Crown Molding Drip Edge Detail

Crown Molding Drip Edge Detail

- (4 images)

- Hits: 15,659

-

Eave Crown Molding Drip Edge Detail

Eave Crown Molding Drip Edge Detail

- (0 images)

- Hits: 0

Drip Edge Images

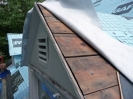

- Curved "eyebrow" drip edge Right

-

Description:

Copper drip edge installed correctly on a curved "eyebrow" roof dormer. This drip edging is properly fabricated with professional sheet metal roofing tools to follow the curves of the dormer roof and trim.

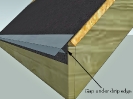

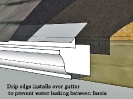

- Pre-made drip edge at eaves

-

Description:

Installing pre-made drip edge flashing at the eaves often leaves a gap under the drip edge and little room to nail the flashing. This results in little support for the shingles and often a raised edge.

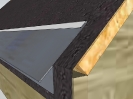

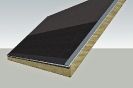

- Drip edge with proper angle

-

Description:

Eave drip edge installed correctly over ice and water shield, and under shingle underlayment. The metal has been bent to accomodate the pitch of the roof.

Restricted Categories

Restricted Categories